Industrial hemp is a versatile plant with hundreds of uses in manufacturing. Unlike marijuana, another plant in the cannabis family, industrial hemp contains less than one percent THC, or Tetrahydrocannabinol, the psychoactive chemical that creates a “high” feeling in marijuana users. Industrial hemp usually also has a hollow stem and high fiber content while marijuana is relatively low in fiber, with a solid stalk. It is grown specifically for industrial purposes and manufacturing, and has been in use for over ten thousand years.

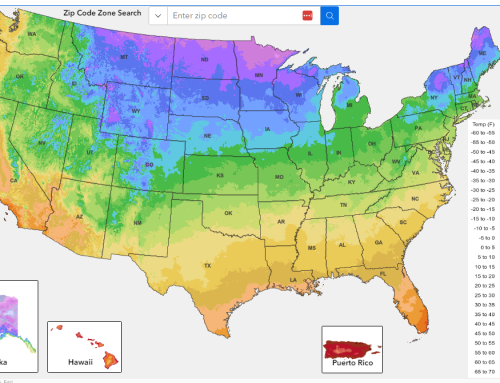

Hemp is best grown in soil types similar to corn, well aerated loam with good drainage. Unlike corn, however, hemp prefers soil to have a pH of six to seven and a half. Industrial hemp also

Hemp is generally planted towards the end of May and the beginning of June, a little before the planting dates for corn. Under ideal conditions, hemp cna germinate in as little as three to five days after the seeds have been sown. Hemp is a short day plant, meaning it only grows when the day lengths are less than twelve hours. For the first sixty days, plants grow incredibly fast. Hemp has even been known to grow up to ten centimeters a day during the peak growing months. Within a month, the plant’s phenotypes begin to show. In August, the plants will begin to shed pollen, which indicates that the hemp crop is ready to be harvested.

First, the stems are cut a few inches above the soil. This can be done by hand or by machine. Next, the cell binding agent, pectin, is allowed to deteriorate. This process is called retting, and is done by exposing the plant stalks to the natural environment. For this to happen, plants must sit in the field for roughly four weeks depending on the weather. Retting is done so that the fibers will more easily separate from the stem. While retting requires a special machine to turn the stalks in the field, but the stalks are baled with a hay baler. Since the moisture content of hemp cannot exceed fifteen percent, it is imperative that the bales are stored in dry place such as a shed or barn.

After this, the fiber is separated from the core with a hammermill. A hammermill is a machine that uses small blows from tiny hammers to break the hemp apart. Following separation, the hemp fiber is cleaned and sorted by desired thickness and strength. Lastly, the hemp is compressed and packaged, then sold and shipped to manufacturers. Hemp fiber can be sold for around 260 dollars per ton. The yield per acre is highly variable, with farmers harvesting anywhere from three and a half to almost nine tons of fiber per acre. Once sold, the fiber has many possibilities for manufacturing, including clothing, paper, building materials, and eco-friendly plastic replacements.

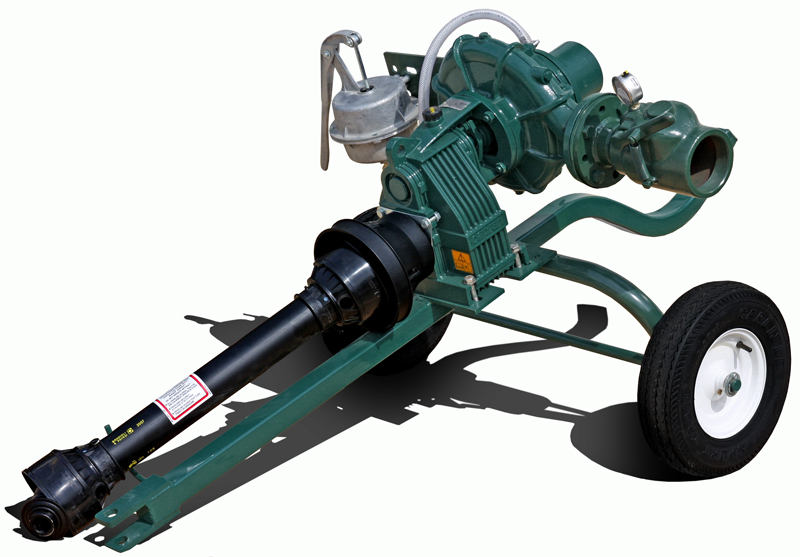

Growing industrial hemp for its versatility in manufacturing has been increasing as more states allow hemp crops to expand. Hemp crops are a lucrative choice, with a great deal of potential for environmentally friendly products being developed as well as expanded use of hemp oils and seeds. More and more industrial hemp will be needed as the demand for recyclable and biodegradable, but tough and durable, products are needed. Contact IrrigationSupplyParts.com for all your industrial hemp crop irrigation parts and equipment.